- Taiyuan automatic terminal machine manufacturing

- Texas domestic automatic terminal machine

- Automatic terminal machine

- Causes of poor contact with the silent terminal machine?

- Terminal machine should pay attention to the use of matters

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: [email protected]

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Maoming stripping tape hitting terminal machine manufacturer

MaomingStripping and tapping terminal machineProduction Manufacturer

Automatic terminal machinePreparation before operation: (1) Check whether the original imported crimping machine and die are installed firmly, Whether the foot switch and the power socket are plugged in securely. (2) Check whether the power supply voltage is consistent with the specified voltage (220V). (3) Fix the terminal roll and guide the terminal into the die through the guide plate. (4) Adjust the crimping height of the stripping and crimping machine, and manually operate the crimping test terminal. (5) After turning the spindle into place with an open-end wrench, remove the open-end wrench.

The automatic terminal machine peels badly: the peeling time varies. There are many reasons for different stripping lengths. The common stripping length is too tight or too loose. At this time, it is only necessary to properly adjust the open space between the two wheels until the wire cannot be pulled by hand. On the other hand, this may be a problem with the blade. The blade is cut too deep or too shallow, and even the blade is installed at an angle, which may also cause this result. At this time, it is necessary to adjust the position of the blades as needed. If it is caused by damage to the blade, it is recommended to replace the blade immediately. Inconsistent cutting lengths Inconsistent cutting lengths may be due to blade or blade wear; to encounter such a problem, simply replace the cutter with a new one.

The automatic terminal machine pressure is too large or other problems, check and debug to OK. Before operation, check each locking screw and confirm that there is no looseness inside. When the blade of the automatic terminal machine has undergone 200,000 times of stamping, there will be a certain degree of wear. At this time, the riveted terminal may have defective products. The cutting blade of the equipment has experienced 1 million or even 2 million times. After the cutting and stripping, there will be certain hidden dangers. Therefore, in the use process of high-demand customers, it is necessary to strictly control the service life of the wearing parts, and the correct operation of the equipment can also reduce the loss.

Talking about the functional advantages of the automatic terminal machine: The advantages of the automatic terminal machine are introduced as follows: the automatic terminal machine refers to a machine used in wire processing, also known as The automatic stripping and pressing end machine is a new type of equipment that has just been released in recent years. It is a multifunctional machine that integrates feeding, cutting, stripping and pressing ends.

Supply the advantages of the terminal machine: high precision, fast speed, stripping, twisting and crimping detection system. The digital control interface uses the integrated working power of light, electricity, machine, gas and magnetism, and imported electrical accessories, which are easy to operate and save time. Technical features: Vibration plate tailored to the sample, linear vibration arrangement device, and precise counting control device can ensure the accuracy of each bag. The packaging material can be determined according to customer requirements. The advanced step control of the machine and the color code tracker can be used together to obtain a perfect trademark pattern.

The possible cause is that the wire feed wheel is too tight or too loose. At this time, we can fine-tune the gap between the two wheels with a steel wire roller, so that the steel wire will not become flat and too loose. The principle is roughly similar to the peel length. 2. Automatic terminal machine failure: bad crimping terminal bad crimping terminal may lead to complete crimping, or not reaching a better crimping position, resulting in bare copper wire. At this time, it is necessary to check whether the gun-type swing arm catheter is installed on the wire. Whether the terminal blade of the swing arm catheter is relatively straight; whether the auxiliary pressing block of the terminal is loose; check whether the interval between the terminal and the automatic machine has been changed.

Humanized and intelligent high-end technology products, suitable for large, medium and small enterprises, saving labor. The advantages of the automatic terminal machine are high precision, fast speed, and have stripping, twisting and crimping detection systems. The digital control interface uses the integrated working power of light, electricity, machine, gas and magnetism, and imported electrical accessories, which are easy to operate and save time.

If the Maoming stripping terminal machine manufacturer is not smooth, the cutting knife is not clean and the feed is not allowed, etc. How to maintain Dongguan Julun mechanical terminals for the mold blades of the terminal machine Maintenance of machine blades. The application of the blade in the automatic terminal machine is very important. If the automatic terminal machine blade is installed and used incorrectly, the 2113 will cause a lot of noise during wire harness processing and cutting. It not only causes damage to the automatic terminal 5261 machine itself, but also brings health risks to the operators.

Maoming stripping machine manufacturer

The semi-automatic terminal machine wire processing project requires manual participation, suitable for all kinds of complex shielded wires, multi-core wires, and separate terminal steps. The terminal machine and the automatic terminal machine have the same points: simple operation and quick use, which are different from the previous manual crimping method, which greatly improves the production efficiency. Improve production capacity for the factory. At the same time, it also saves a lot of costs for the factory. Dongguan Julun Machinery Co., Ltd. is at your service. Consulting Tel: 0769-87883409

Maoming stripping machine manufacturer

Julon automatic terminal machine closing height (crimping height) adjustment: automatic terminal machine when the closing height is not appropriate or the mold crimping height micro adjuster plate adjustment is not enough , Can be achieved by adjusting the adjustment joint and loosening the round nut. Insert the adjusting rod into the round hole on the adjusting joint and turn it. Turning left will decrease the pressing height, and turning right will increase the pressing height (the engraved line on the adjusting joint is 0.1mm per grid, and one turn is 3mm). From high to low, adjust to the proper compression of the wires and terminals. It should not be too tight. Too tight will easily damage the upper and lower die blades.

Maoming stripping machine manufacturer

Dongguan Julun Machinery Co., Ltd. adheres to the quality policy of "quality first, pursuit of customer satisfaction, continuous innovation, and endless improvement" to serve customers. It insists on purchasing reliable raw materials, advanced equipment and 1653 technology; it implements strict scientific management and fast on-time delivery, strict quality control, and production updates. Better computer wire stripping machines, terminals and other products can meet the needs of domestic and foreign markets. At the same time, the details of the production process are strictly controlled internally. In order to achieve higher quality assurance.

-

2021-07-23 15:23:54Automatic terminal machine production precautions

-

2021-07-24 14:40:06Super silent terminal machine

-

2021-07-23 15:24:15How should the automatic terminal machine maintenance?

-

2021-07-24 14:18:51Ningbo automatic terminal machine brand

-

2021-07-23 17:10:31Wuhu automatic terminal machine factory

-

2021-07-23 16:46:05Huzhou terminal machine cost

-

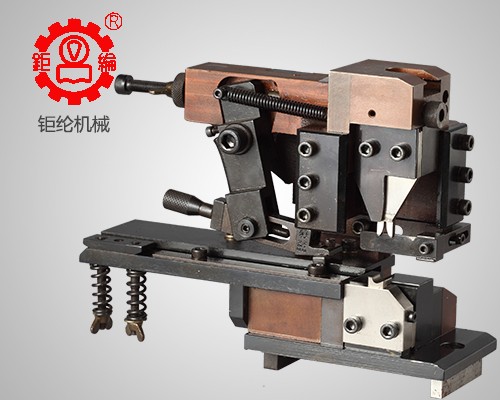

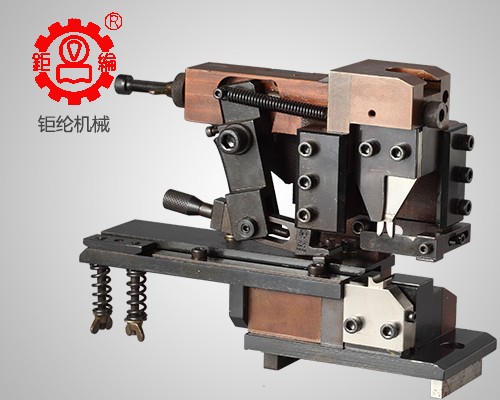

C1-3.0A Terminal Machine

-

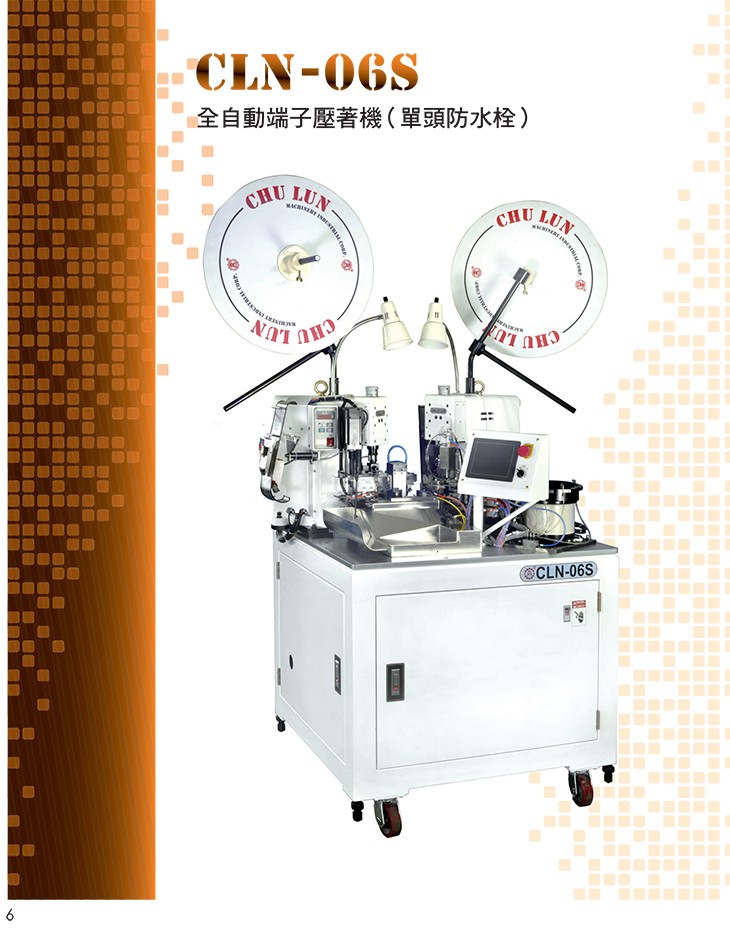

Fully Automatic Terminal Crimping Machine (Single Head Waterproof Bolt)

-

CLM-2S card module

-

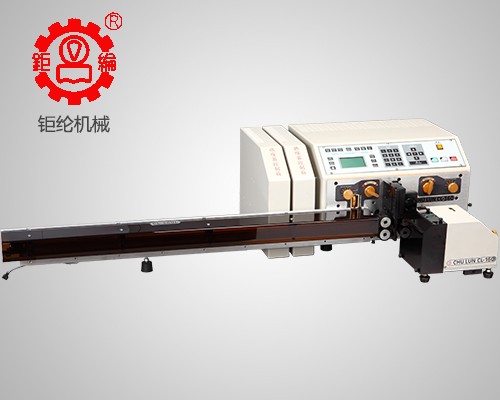

CL-360+160+260L Automatic Computerized Wire Cutting Machine

-

CL-CWSS Single-head pole short wire dip tin machine

-

CLN-05CHS Automatic Double Head Solder Dip Machine

-

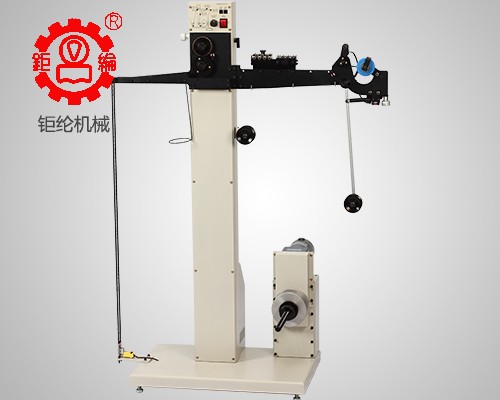

WRS-02 Multifunctional Wire Feeding Machine

-

CLN-05-CH Automatic Automatic Termination Solder Dipping Machine

EN

EN

CN

CN

QQ customer service

QQ customer service