- Automatic terminal machine history and future?

- Causes of poor contact with the silent terminal machine?

- Taiyuan automatic terminal machine manufacturing

- Lianyungang stripping tape hit terminal machine processing

- Terminal machine should pay attention to the use of matters

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: [email protected]

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

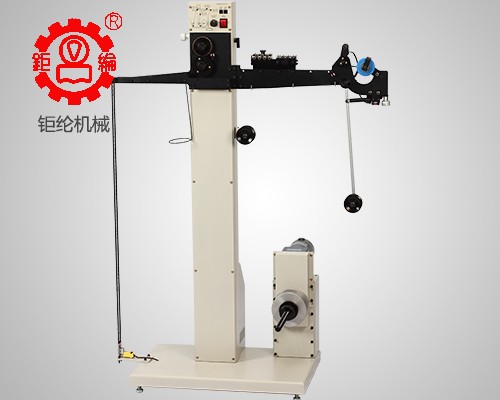

Semi-automatic terminal machine

Semi-automatic terminal machine

Automatic terminal machine is one of the products we use more, but there is another product that is semi-automatic terminal It means that half of this kind of products is also required manual. The two are different terminal machine equipment, so the working methods are also different. It can be said that the difference is still quite big, but we have Have you understood the main difference between the automatic terminal machine and the semi-automatic terminal machine?

Ultra-quiet terminal machine operators must go through professional technical training, and they can only work after passing the training. Before operation, confirm whether the power and air source of the machine are normally connected, and confirm whether each part of the ultra-quiet terminal machine is in the normal position. If it is not in the normal position, manually adjust it to return to the normal position; clear the obstacles around the equipment. Carefully adjust the parameters according to the wire model and save. Before the equipment is running, do not directly press the "Start" button, but press the reset button to reset the equipment first. If the reset button keeps flashing at this time, you can press the "Single Step" button first, and then press the "Reset" button, the flashing will disappear. After the device is reset, press the "Single Step" button and then the "Start" button to make the device run a cycle step by step to check the operation.

1. The automatic terminal machine is fully intelligent and automatic. It integrates integrated circuits, servers, manipulators, detection signals, and integrates all the production processes of wire processing into one power supply Line processing equipment. A lot of manual operations can be saved during operation, only the operation method needs to be set, and a work signal is given to the server. This signal will be transmitted to the work drive motor through a series of components, and then the work can be started and stopped. The entire work process is completed automatically, so work efficiency is higher and manpower can be saved.

If the relay is broken,Ultra-quiet terminal machineIf the inverter motherboard of the ultra-quiet terminal machine is not broken, there is a problem with the relay. How to set the mute terminal inverter inverter. Where to buy the terminal machine inverters made by each manufacturer is different, you can refer to the manual to set up. Luoyang ultra-quiet terminal machine will not move after a long time. Look at the terminal machine motor and pedal. Is there something wrong with the circuit? It is possible that the copper sleeve is stuck, so try adding some oil.

Semi-automatic terminal machine

2. Semi-automatic terminal machine is a more common terminal machine equipment, we all refer to it collectively as terminal machine. Semi-automatic terminal machine used to be the most used equipment on the market because of its strong applicability. The semi-automatic terminal machine is controlled by a foot-operated power-off clutch device through manual foot-stepping to control the machine's terminal action. The processing action of the semi-automatic terminal machine is single, as long as the terminal is tapped, and the wire material also requires manual separation and wire feeding. The work efficiency is lower than that of the automatic terminal machine.

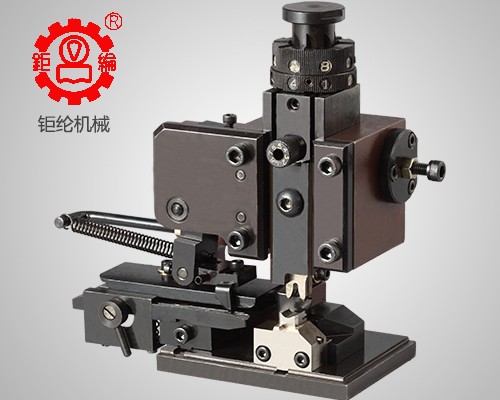

Where to buy terminal machine debugging is mainly mold debugging, and this part of the mold is divided into feeding and blade debugging, where to buy terminal machine blades generally have 4 blades, divided into The upper knife is 2 pieces, the lower knife is 2 pieces, the upper knife is divided into the inner knife and the outer knife, and the ultra-quiet terminal machine is the same as the lower knife. You understand that the next step of debugging is much easier. You must perform manual debugging. One is safe , And we can see whether the crimped terminal meets the requirements by manual debugging. The terminal crimping grid mainly depends on the crimped copper wire, because this is conductive, so the key is too tight, it will press the copper wire If it is broken or it will break the blade directly, the terminal and the wire will easily fall off if it is loosened. Please do it more. I think you will be familiar with this one.

Semi-automatic terminal machine

Because the price of fully automatic terminal machines is higher than that of semi-automatic terminal machines, most of the terminal machines of many companies are still semi-automatic terminal machines. However, with the progress of the times, fully automatic terminal machines have become the core equipment of automated wire processing enterprises. Following the development of enterprises, fully automatic terminal machines will gradually replace semi-automatic terminal machines. This is the future direction of the enterprise.

Semi-automatic terminal machine

The ultra-quiet terminal machine should be checked first, clean it up, add oil or butter, try the empty knife three times, and observe if there is any return of the knife. If you find a problem, you should promptly Ruled out, during the production process, if a knife is found to be returned, the vehicle should be parked immediately, and repaired in time is not allowed to operate with disease. 2. When the ultra-quiet terminal machine is working, thinking must be concentrated, and it is strictly forbidden for two people to operate the paper cutter at the same time. 3. When the machine is running, it is strictly forbidden to reach into the machine. If a fault occurs, it is strictly forbidden to grab the paper by hand. The machine should be shut down immediately.

If you need these two products or terminal molds, terminal copper strips, piercing terminals, automatic pipe cutting machines and other mechanical equipment, you can contact our semi-automatic terminal machine manufacturer , Welcome our calls.

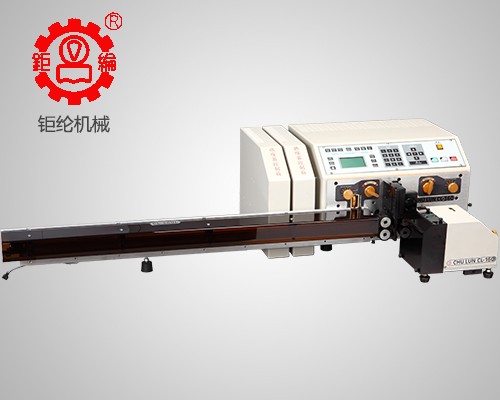

The semi-automatic terminal machine computer wire cutting machine is mainly used for stripping after cutting the wire harness. I think Dongguan Julun Machinery Co., Ltd. has done a very good job in this aspect. In the process of work The failure of the computer thread cutting machine is a big test for the staff. If it cannot be handled in time, it will have a great impact on the production progress of the machine and the product. To ensure that the operation of Dongguan Julun Machinery achieves great value, please refer to The following is the way to deal with some daily failures of the computer wire cutting machine.

Semi-automatic terminal machine

Semi-automatic terminal machine

The semi-automatic terminal machine is conductive, so the key point is that too tight will crush the copper wire or directly break the blade, and loose it will cause the terminal and the wire This part is easy to fall off. You can do it more. I think you will be familiar with this one. If you have done the operation and you still don’t understand, you can call: 0769-87883409 Dongguan Julun Machinery Co., Ltd. Where do we buy terminals? Machine, wire stripping machine manufacturer, will let you understand the debugging method of the terminal machine

- Prev: Wire cutting machine

- Next: Automatic terminal machine

-

2021-07-23 16:40:15Lianyungang stripping tape hit terminal machine processing

-

2021-07-23 16:59:23Taiyuan automatic terminal machine manufacturing

-

2021-07-24 15:38:30Suqian professional manufacturing computer wire cutting machine

-

2021-07-23 15:23:54Automatic terminal machine production precautions

-

2021-07-23 17:05:13Texas domestic automatic terminal machine

-

2021-07-23 17:07:42Original automatic terminal machine manufacturers

-

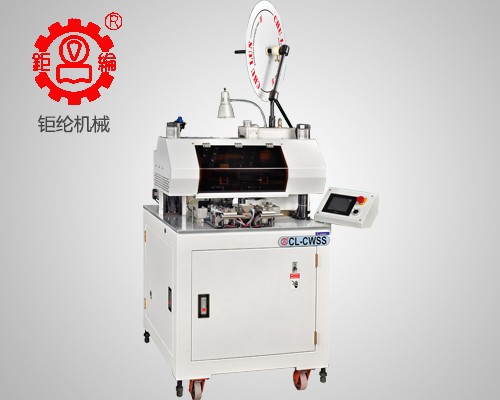

CL-CWSS Single Head Short Wire Solder Dip Machine

-

WRS-02 Multifunctional Wire Feeding Machine

-

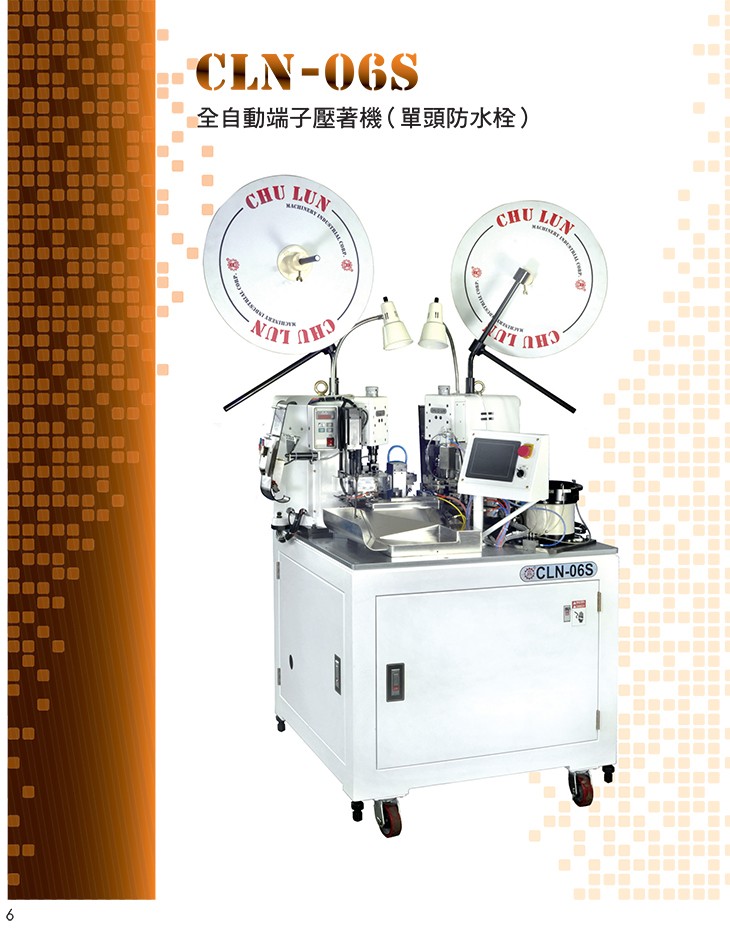

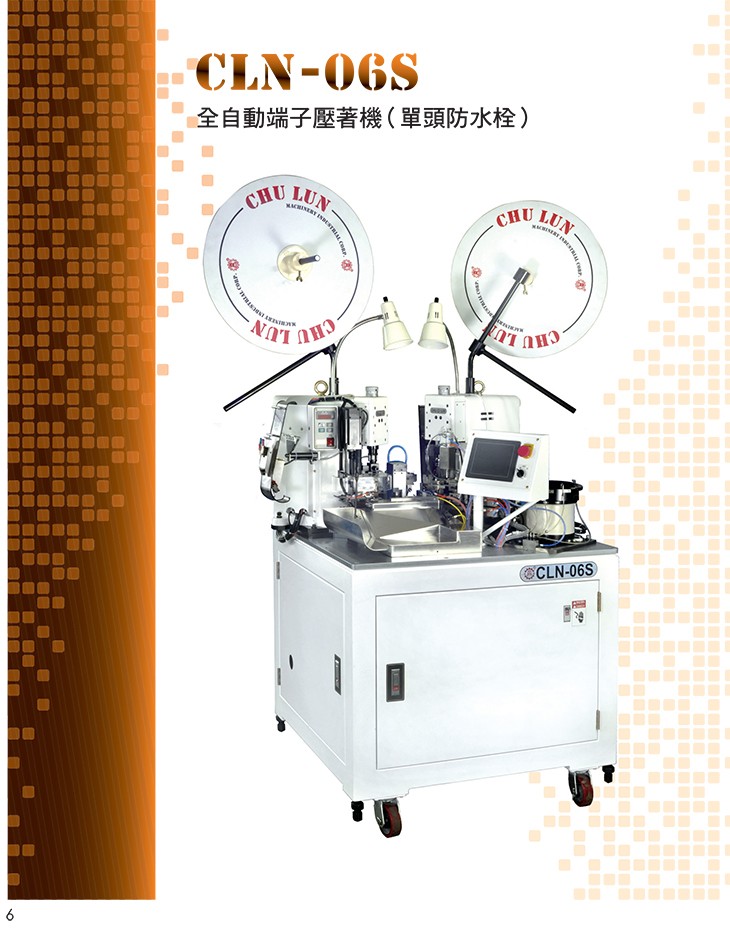

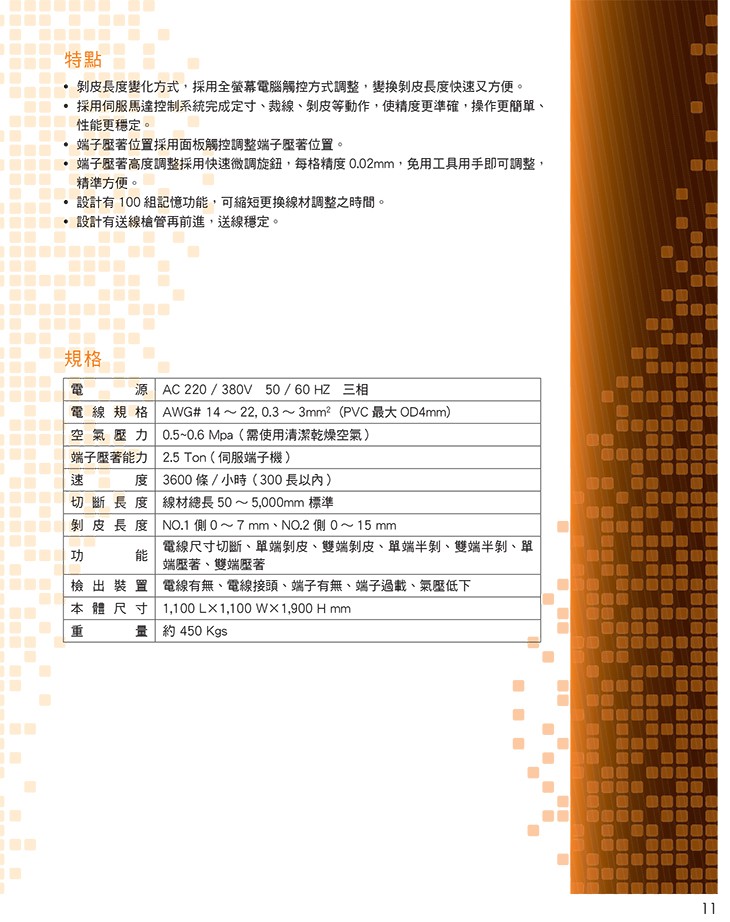

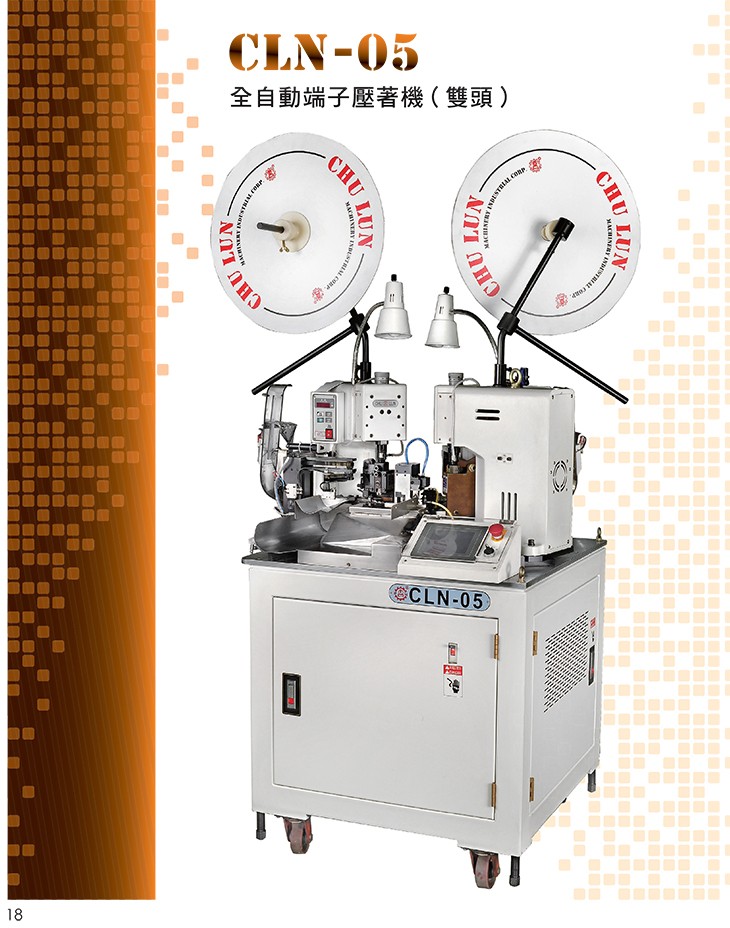

CLN-05 Automatic Terminal Crimping Machine (Double Head)

-

CLM-3W Card Module

-

CL-360+160+260L Automatic Computerized Wire Cutting Machine

-

CLN-05-CH Automatic Automatic Termination Solder Dipping Machine

-

Waterproof pins

-

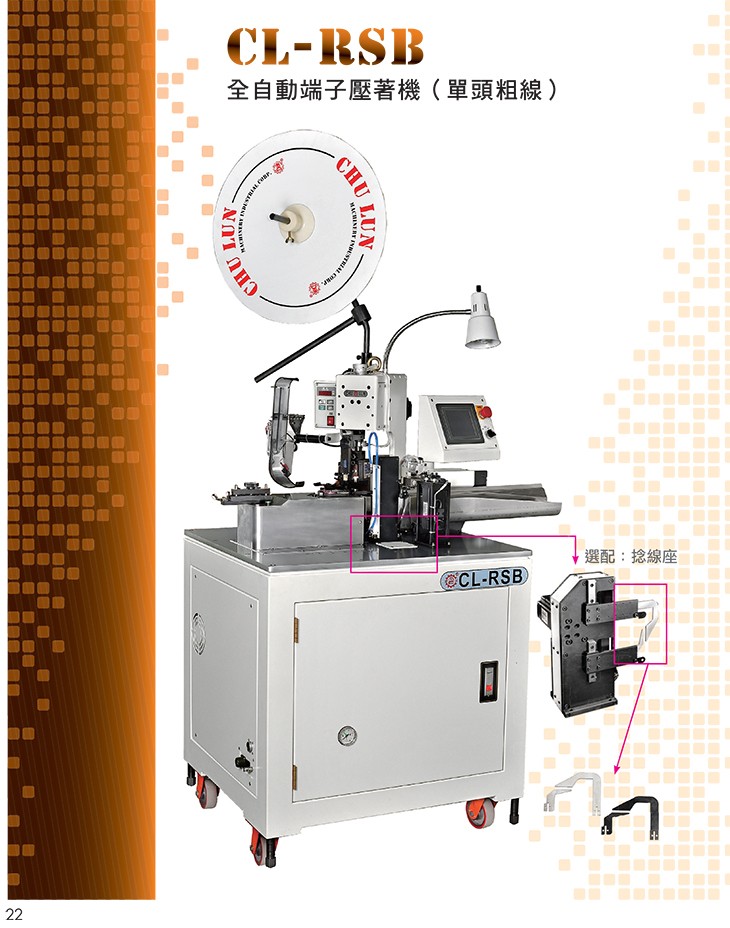

CLN-06 Automatic terminal crimping machine (thick wire)

EN

EN

CN

CN

QQ customer service

QQ customer service