- Semi-automatic terminal machine

- Terminal machine

- Wire cutting machine

- Erdos terminal machine for sale

- Xi'an special price super quiet terminal machine

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: [email protected]

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Super silent terminal machine introduction

Ultra-quiet terminal machine is the use of modern inverter control skills, is developed for common terminal molds at home and abroad, suitable for For the crimping of various terminals and wires. Digital control, safety protection system, and simple operation complete the precision, strength and safety beyond the reach of machinery. It makes the terminal machine ultra-quiet operation, and the inverter itself can save power by 30%. In addition, the ultra-quiet terminal machine is energized once at a time, avoiding unnecessary idling of the motor and saving electricity when used. There is no noise, and workers are more focused on work, which greatly improves work efficiency. This is the equipment for processing the end of the wire. Ultra-quiet terminal machine

Function modification of ultra-silent terminal machine

Equipped with otp long mode; [1] 2, this machine uses electronic induction positioning frequency conversion convergence; 3, this machine saves electricity, no power consumption when waiting for operation , There is no sound during operation; 4. The machine has no trouble at all, but the oil bridge on the machine head must ensure the organic oil.

Parameter modification of ultra-quiet terminal machine

Power supply: ac220v/50hz Power: 400w Slide stroke: 30mm Large closing height: 150mm Close height adjustment: 10mm Pressing times: 150/min Dimension: 350×390× 500mm nominal pressure: 20kn weight

Effect modification of mute terminal machine

Silent terminal machine refers to a machine used in wire processing, which can press the metal head to the wire end. Then conduct conduction. The terminals produced by the silent terminal machine are generally for more convenient connection. The two wires can be connected together stably without soldering, and only need to be unplugged when disassembling.

Ju Lun Machinery Industry Co., Ltd. was established in Taiwan in 1964. It was transferred to the production of terminal machines and wire cutting machines in 1969. With hard work, we then designed and launched automated machinery.

Taiwan Headquarters has been established for more than 40 years, upholding the pursuit of business philosophy, from development and design to production, using consistent operations, the company uses a computer management system, and will develop and design , Financial management, material management, customer orders, etc., are all incorporated into the company’s computer management system.

Dongguan Julun Machinery Co., Ltd. branch was established in Dongguan City, Guangdong Province in 1997. Mainly responsible for the integrated production of sales machines and mold blades. Serve all inland customers who need it.

Because of the deep support from all walks of life, the company has made every effort to improve the quality of machinery. For this reason, the company’s triple factory invested 120 million in funds to introduce Japan’s Toshiba company" Type precision integrated machining center" invests in parts processing and machine body processing to make the quality and size of the machine precise and accurate.

In recent years, in order to meet the needs of various industries in the future, the company has continued to invest and develop high-capacity machinery to provide the industry with more automated machinery to achieve the goal of reducing costs and improving competitiveness. To honour the advanced care of all walks of life.

The company will uphold the service industry, improve the quality of terminal machines and wire cutting machines, and continue to move forward with new and new, with a view to becoming the world's terminal machine and wire cutting machine manufacturing company.

-

2021-07-24 14:30:15Super silent terminal machine introduction

-

2021-07-24 14:29:50Shenzhen multiplayer exhibition fl

-

2021-07-24 14:29:16Silent terminal machine inspection method

-

2021-07-24 14:35:41Strip tape hitting terminal machine

-

2021-07-23 15:22:10How to effectively reduce the danger of operating the terminal machine?

-

2021-07-24 14:26:42Binzhou where to buy terminal machine

-

CLT-C2S with stripping and beating terminal machine

-

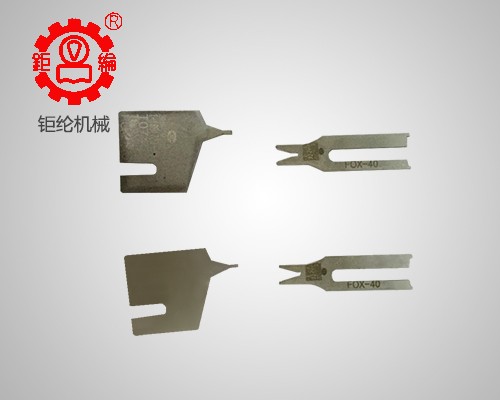

CN peeling knife

-

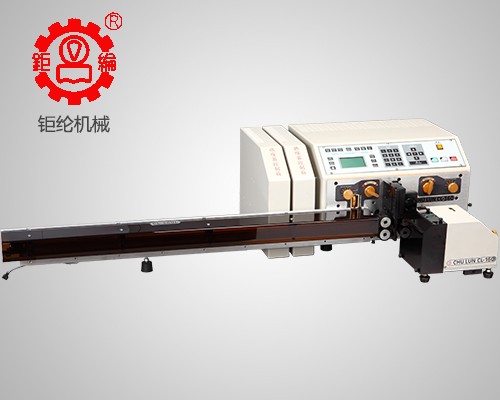

CL-360+160+260L Automatic Computerized Wire Cutting Machine

-

C3-2.5 CNC type terminal machine

-

Waterproof pins

-

Special crimping knife

-

Fully Automatic Terminal Crimping and Twisting Wire Solder Dabbing Machine (Single Head Waterproof)

-

CLN-05 High Speed Double Ending Machine

EN

EN

CN

CN

QQ customer service

QQ customer service