- Intelligent terminal machine

- Huzhou automatic terminal machine processing factory

- Maoming stripping tape hitting terminal machine manufacturer

- Texas domestic automatic terminal machine

- Super silent terminal machine introduction

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: [email protected]

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Dongguan regular ultra-silent terminal machine

Dongguan officialUltra-quiet terminal machine

Fully automatic terminal machineIt is still a kind of mechanical product that is used more in our lives. It should be understood! Also, because this kind of product is fully automatic, the hours and minutes used are much more convenient, and the work efficiency can be improved a lot, but no matter what it is, we must learn to maintain it when we use it. If it is well maintained, then we use it. It can also extend its use time when it gets up, but what should we pay attention to when we enter the field for maintenance?

Dongguan regular ultra-quiet terminal machine is conductive, so the key point is that too tight will break the copper wire or directly break the blade. If it is loose, it will let The terminals and wires are easy to fall off. You should do it more. I think you will be familiar with this one. If you still don’t understand during the operation, you can call: 0769-87883409 Dongguan Julun Machinery Co., Ltd. We are a professional professional Manufacturers of terminal machines and wire stripping machines will surely let you know how to debug terminal machines

Dongguan regular ultra-quiet terminal machine

Automatic terminal machine maintenance precautions

1. It is necessary for the staff to clean the machine every day to remove the dust, debris and remaining oil on the surface of the machine.

Dongguan’s regular ultra-quiet terminal machine realizes “ultra-high-speed processing” of fully automatic crimping at both ends of 9000 pieces per hour! Equipped with standard equipment for pressure testing! The "simple|small" stripping terminal machine has unprecedented performance and amazing processing capabilities. It is a next-generation fully automatic crimping machine that has completely changed the concept of wire processing machines. This model has original ideas and creations, which not only improves the performance of the machine, but also reduces the burden on the operators through the simplification of operating procedures and die exchange. In addition, from the operator's point of view, the stripper and terminal machine greatly reduces the size and realizes the miniaturization of accessories, which saves space.

2. The crimping part of the automatic terminal machine must be added with butter every week, and evenly spread on the surface of the high-speed bearing and around the press block.

Dongguan regular ultra-quiet terminal machine removes the wire from the professional production terminal machine, and checks whether the effect of the terminal on the wire can meet the requirements. If it does not meet the requirements, you need to re-adjuststripping and tapping terminal machinedevice. After confirming that the specifications and effects meet the requirements, the sample line will be submitted to PQC for inspection. After passing the PQC inspection, mass production will begin. Arrange the wires with the terminals neatly, and tie every 100 wires or every 50 wires together with rubber hoops as required, and then place them neatly in the plastic basin.

Safety inspection of Dongguan regular ultra-quiet terminal machine automatic terminal machine before operation: (1) Confirm that the wrench has been removed. (2) Tighten the round nut after adjustment. The automatic terminal machine runs normally: (1) Press the operating switch to the working position, and the stripping terminal machine motor starts to run. (2) Place the wire in the proper position of the terminal crimping position, and the crimped terminal must be in the middle of the upper and lower die cutters. (3) Step on the foot switch, and the main slider will push down to complete the crimping of the wire and the terminal, and send the next terminal to the crimping position. (4) Repeat the above steps to achieve continuous crimping between the wire and the terminal.

Dongguan regular ultra-quiet terminal machine

3. It is necessary to add oil to the stamping guide rail of the automatic terminal machine once an hour. The smooth oiling hole is on the top of the terminal machine. It is advisable to use 2-3 drops each time. .

Professional production of stripping and crimping machine is a semi-automatic model. As the name suggests, it has the functions of automatic peeling and crimping of the terminals, but it requires manual feeding and manual control of the foot power switch to work. The production efficiency is high and the price is low. The ultra-quiet terminal machine servo (inverter) is a professional production terminal machine, which is a semi-automatic model and requires manual feeding and manual control of the pedal power switch to work. The working principle is similar to the stripping terminal machine, but it does not have the automatic thinning function (usually used in conjunction with the computer wire cutting machine), low energy consumption and low price.

The daily maintenance precautions of the automatic terminal machine have been introduced here. You can learn more about it, and we should pay more attention to it when we use it. We have better assistance. We should be more careful when using the automatic terminal machine. If you need to buy automatic terminal machines, automatic pipe cutting machines, corrugated pipe cutting machines and other mechanical equipment. Contact us by phone, and we also have punctured terminals, terminal molds, terminal copper strips and other accessories. If you need them, please contact us by phone.

You do it more, I think you will be familiar with this one, if you still don’t understand it during the operation, please call: 0769-87883409, Dongguan Julun Machinery Co., Ltd. The company, we are a professional terminal machine, specialized in the production of wire stripping machine manufacturers, we will definitely let you understand the debugging method of the terminal machine; how many square wires should be used and how many tonnage professional production terminal machines. Terminal machines can be classified as fully automatic terminal machines , Even stripping terminal machine, ultra-quiet terminal machine, pneumatic terminal machine, terminal terminal machine, computer wire automatic stripping terminal machine, pin terminal machine, gold wire terminal machine, etc.

Dongguan regular ultra-quiet terminal machine

Dongguan regular ultra-quiet terminal machine

Dongguan standard ultra-quiet terminal machine automatic terminal machine manual operation: <1> Turn the operation switch to the adjustment position ○1 (POWEROFF) and the motor will not run at this time. <2> Insert the open-end wrench into the main shaft from the rear door, and press the manual button ○2 (ADJUST) to attract the solenoid. <3> The open-end wrench rotates clockwise to drive the main shaft to rotate one round, the main machine slide block moves up and down to complete a stroke, and a terminal is crimped. <4> Keep pressing the manual button ○2 to turn it in place continuously, and then remove the open-end wrench.

-

2021-07-23 16:40:15Lianyungang stripping tape hit terminal machine processing

-

2021-07-24 15:15:48Automatic terminal machine

-

2021-07-24 15:58:23Xianyang small semi-automatic terminal machine

-

2021-07-24 14:06:14Maoming stripping tape hitting terminal machine manufacturer

-

2021-07-24 15:38:30Suqian professional manufacturing computer wire cutting machine

-

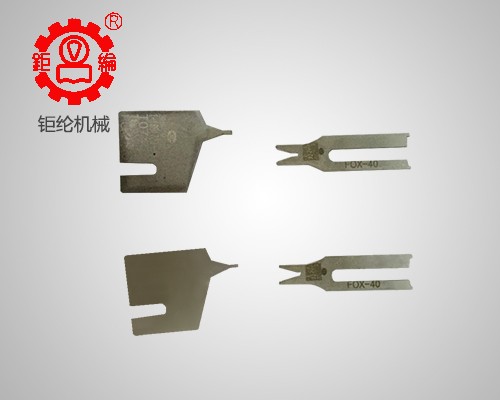

CLM-4E card die

-

CLN-05 High Speed Double Ending Machine

-

Special crimping knife

-

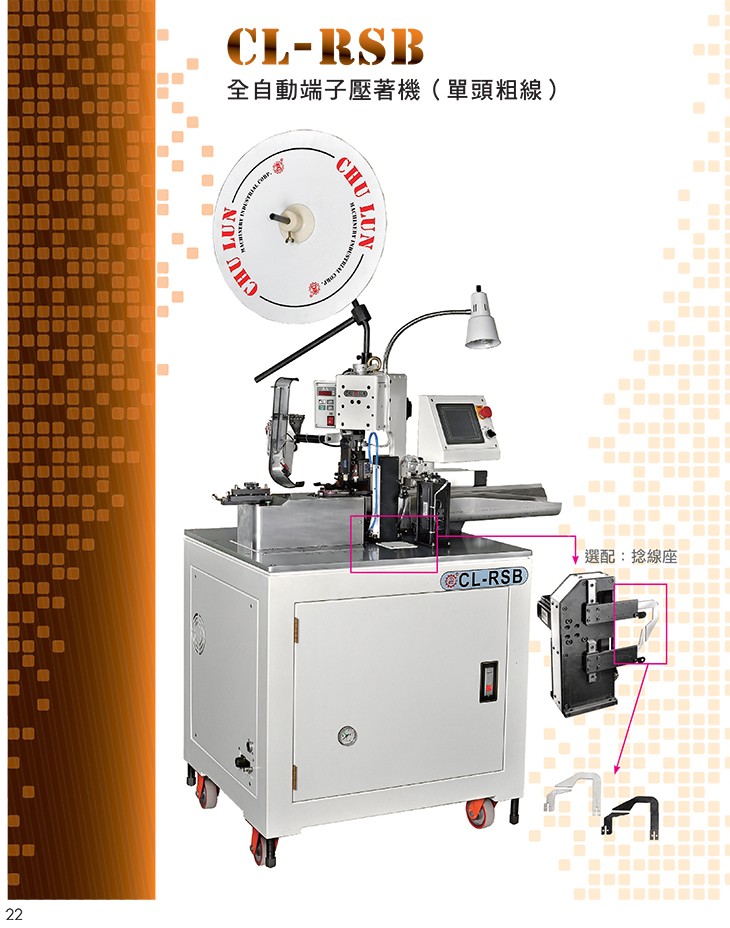

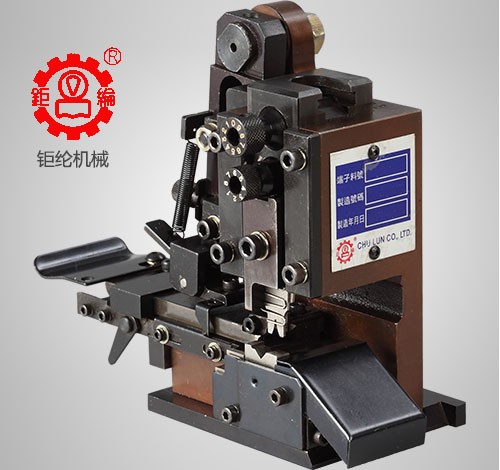

CL-RSB Automatic Terminal Crimping Machine (single head thick wire)

-

C3-5.0A CNC type silent terminal machine (5T)

-

CLN-05 Automatic Terminal Crimping Machine (Double Head)

-

WRS-04+05 Shaft loading type wire release machine + wire feeder

-

CLN-05-CH Automatic Automatic Termination Solder Dipping Machine

EN

EN

CN

CN

QQ customer service

QQ customer service