- Original automatic terminal machine manufacturers

- Erdos terminal machine for sale

- Ningbo automatic terminal machine brand

- Tangshan where to peel the tape hitting terminal machine

- Super silent terminal machine introduction

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: [email protected]

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Maoming automatic stripping tape hitting terminal machine

Maoming AutomaticStriping terminal machine

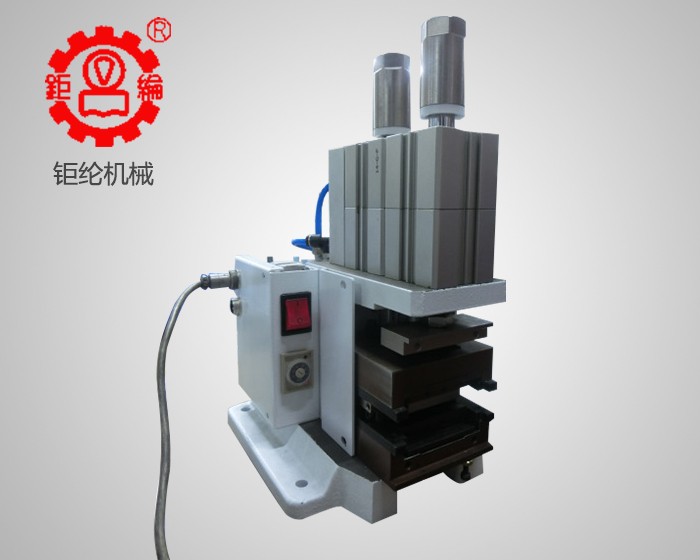

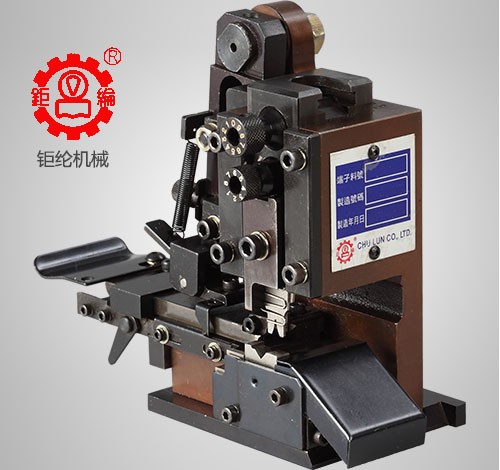

Terminal machine, a multi-function machine integrating feeding, cutting, stripping, and end pressing, humanized and intelligent high-end technical products, suitable for large, medium and small companies , Save labor. Chinese touch screen display settings, wire processing size, knife depth, terminal orientation...simplified, easy to learn and understand, repair consumables cost low. It can quickly and effectively increase production power, reduce labor costs, increase the company's profitability, and bring a certain boost to the company's livelihood development.

When replacing wires, terminals, molds, or cleaning the Maoming automatic stripping terminal machine, you must first cut off the stripping terminal Replace the terminal while it is running. When the stripping terminal machine is blocked or stuck in the terminal, you must disconnect the power supply of the device first, and then use tweezers and other tools to remove it. It is strictly forbidden to reach into the machine or mold. During operation, if you need to leave the work post, you must turn off the power before leaving. Do not operate the switches or adjustments of electronic components at will. Incorrect changes may cause accidents due to loss of control of the machinery.

Full-active terminal machine: a terminal machine that combines a server (silent type). Its operating principle is different from the usual terminal machine, only one is needed for the server Information, this information is then transmitted to the motor, and the all-active terminal machine can perform an action. All assignments are automatically completed,

Maoming automatic stripping terminal machine semi-automatic terminal machine features: semi-automatic terminal machine wire processing project requires manual participation, suitable for a variety of complex shielded wires, For multi-core wires, carry out the terminal step separately. Terminal machine andFully automatic terminal machineThe two have the same point: simple operation, quick use, different from the past The manual crimping method greatly improves the production efficiency. Improve production capacity for the factory. At the same time, it also saves a lot of costs for the factory. Dongguan Julun Machinery Co., Ltd. is at your service. Consulting Tel: 0769-87883409

Maoming automatic stripping and crimping machine specifications and processing dimensions: the front end can be set to a length of 0.1-20 mm, the rear end can be set to a length of 0.1-9.9 mm, processing size L≥ 60mm, cutting length 999999mm, cutting tolerance ±0.2mm, L=cutting length, crimping terminal: continuous terminal, crimping capacity standard 1.2ton, large 2.5Ton, give you a PDF file format command control Method: digital control, external size 650mmx550mmx1210mm, weight 290kg, input power: single-phase ac200v, AC220V, ac240v50/60Hz air pressure: 17nl/min0.6mpa, power: static 300W, power/980W Processing line: applicable wire diameter: AWGᦇ12~AWGᦇ32, Applicable lines: AV, AVS, AVSS, cavus, kV, KIV, UL, etc.

Semi-active terminal machine: usually called terminal machine, which is the kind of vertical desktop terminal machine that we often see in shopping malls nowadays, this kind of terminal machine They all have a pedal-operated power-off clutch. When the terminal machine is running, its motor is constantly running. Each time the pedal is stepped on, it will give an “O” power-off signal to stop the operation. The price of all active terminal machines will be much lower.

Technical features: customized vibration plate, linear vibration arrangement device, sample precision counting control device to ensure the accuracy of each bag. The packaging materials of the stripping terminal machine can be determined according to customer requirements. The machine adopts the combination of advanced step control and color code tracker to obtain perfect trademark patterns. Advanced PLC or single chip microcomputer control system, fault self-stop, self-alarm, self-diagnosis, safe and easy to use. Automatically display the number of packages, which can conveniently count the workload of the machine. Compared with ordinary terminals, automatic terminals have many advantages, and ultra-high-speed automatic terminals have more features than automatic terminals. There are three advantages here.

Maoming fully automatic stripping and tapping machine

Single-head crimping terminal machine: select plc or single-chip control, servo motor or stepper motor to provide power, the production process does not require manual participation, and the production power is high. Now this type of domestic production The equipment can complete about 5000pcs wire cutting, thin-skinned, single-ended crimping terminals per hour, and can actively detect the crimping quality of the terminals.

Maoming fully automatic stripping terminal machine is equipped with well-known terminal machines that need to be punched, and an inner hexagon wrench is used to adjust the feed pressure plate, so that the automatic terminal machine can easily pass through. Whether the feeding position is suitable, if not, adjust it. Use an inner hexagon wrench to loosen the feeder lock screw, turn the adjusting rod to adjust until the machine is in a normal state, and then lock the feeder lock screw to start the operation. Test tension: After the adjustment is OK, take the scrap wire and test it, and conduct a tension test. The main reference values are shown in the "Tension Test Comparison Table". The specific operation method is as follows, press the tension test reset button to reset to zero, and set the terminal to be tested The wire is clamped and tested. If the measured tension is not within the standard range, please re-adjust it by the mechanic until it reaches the standard value.

Maoming fully automatic stripping and tapping machine

What is the technological process of the automatic terminal machine of Maoming automatic stripping machine? Turn on the power switch of the automatic terminal, and the power indicator light is on. Pay attention to whether there are obvious abnormal noises inside and outside the machine. If the operation is suspended, ask the maintenance personnel to determine whether maintenance is required. Knife selection and installation: operated by designated personnel. Before installing the tool, you need to manually compare whether the selected tool matches. The tool can only be installed after the comparison is correct. After installing the tool, it must be tested manually. First of all, turn off the power of the automatic terminal machine, press the down touch button, and use the special board to manually move the master and slave wheels to greatly increase the punching stroke of the well-known terminal press. If the hand does not move, consider whether the pressure is too high or there are other problems, check and adjust to normal. Before operation, check and confirm that the locking screws are not loose.

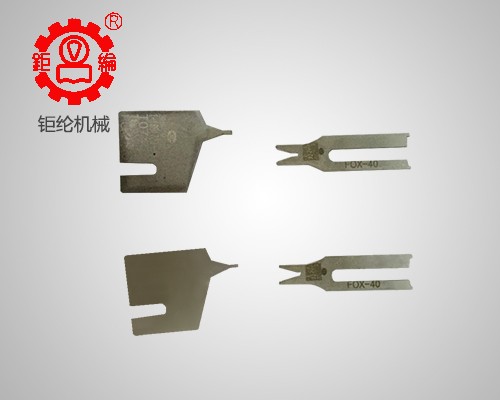

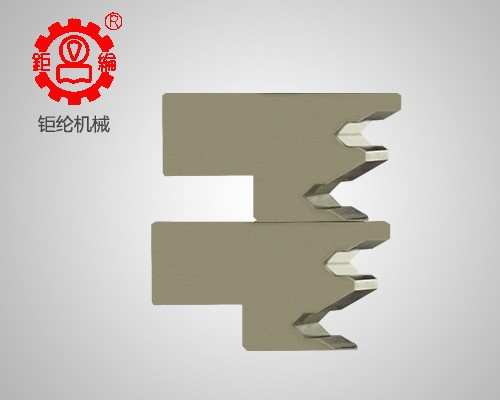

Terminal machine debugging is mainly mold debugging, and this part of the mold is divided into feeding and blade debugging. Generally speaking, there are 4 blades in the terminal machine, and 2 upper and lower blades. There are 2 blades, the upper blade is divided into the inner blade and the outer blade, and the lower blade is the same. You understand that the next step is to debug the stripper and terminal machine. You must debug the stripper and terminal machine manually. One is safe , And we can see whether the crimped terminal meets the requirements by manual debugging. The well-known terminal crimping grid mainly depends on the crimped copper wire, because this is conductive, so the key is too tight. Crushing or breaking the blade directly will cause the terminal and wire to fall off easily if it is loose.

Single-head twisted wire soldering terminal machine: Choose plc or single-chip microcomputer control, servo motor or stepper motor to provide power, the production process does not require manual participation, and the production power is high. Types of domestic equipment can complete about 4000pcs of wire cutting, thin skin, single-ended crimping terminals per hour, single-ended twisting + bonding flux + tinning, and can actively detect the quality of terminal crimping, which is the degree of automation in the domestic market. One of the high terminal machines.

When replacing wires, terminals, molds, or cleaning the Maoming automatic stripping terminal machine, you must first cut off the stripping terminal Replace the terminal while it is running. When the stripping terminal machine is blocked or stuck in the terminal, you must disconnect the power supply of the device first, and then use tweezers and other tools to remove it. It is strictly forbidden to reach into the machine or mold. During operation, if you need to leave the work post, you must turn off the power before leaving. Do not operate the switches or adjustments of electronic components at will. Incorrect changes may cause accidents due to loss of control of the machinery.

Maoming fully automatic stripping and tapping machine

Maoming fully automatic stripping and crimping machine

When replacing wires, terminals, molds, or cleaning the Maoming automatic stripping terminal machine, you must first cut off the stripping terminal Replace the terminal while it is running. When the stripping terminal machine is blocked or stuck in the terminal, you must disconnect the power supply of the device first, and then use tweezers and other tools to remove it. It is strictly forbidden to reach into the machine or mold. During operation, if you need to leave the work post, you must turn off the power before leaving. Do not operate the switches or adjustments of electronic components at will. Incorrect changes may cause accidents due to loss of control of the machinery.

-

2021-07-24 15:31:17Zibo popular automatic terminal machine

-

2021-07-24 14:58:42Computerized Wire Cutting Machine

-

2021-07-24 15:27:22Jining stock intelligent terminal machine

-

2021-07-23 15:23:28Why just purchased back the mute terminal machine will be fixed poorly?

-

2021-07-24 15:22:43Dongguan regular ultra-silent terminal machine

-

2021-07-24 15:34:07Maoming automatic stripping tape hitting terminal machine

-

Special crimping knife

-

Fully Automatic Terminal Crimping and Twisting Wire Solder Dabbing Machine (Single Head Waterproof)

-

CLM-4E card die

-

C1-2.5A Terminal Machine

-

CLS-1T Copper Strip Machine

-

Special cutting knives

-

CL-2000L Super High Speed Automatic Computerized Wire Cutting Machine (Extended Type)

-

WRS-04+05 Shaft loading type wire release machine + wire feeder

EN

EN

CN

CN

QQ customer service

QQ customer service